We are your number 1 manufacturer specialist of Shouldered Ends

Advanced Piping has a BRAND NEW range ready for fast dispatch and no lead time!

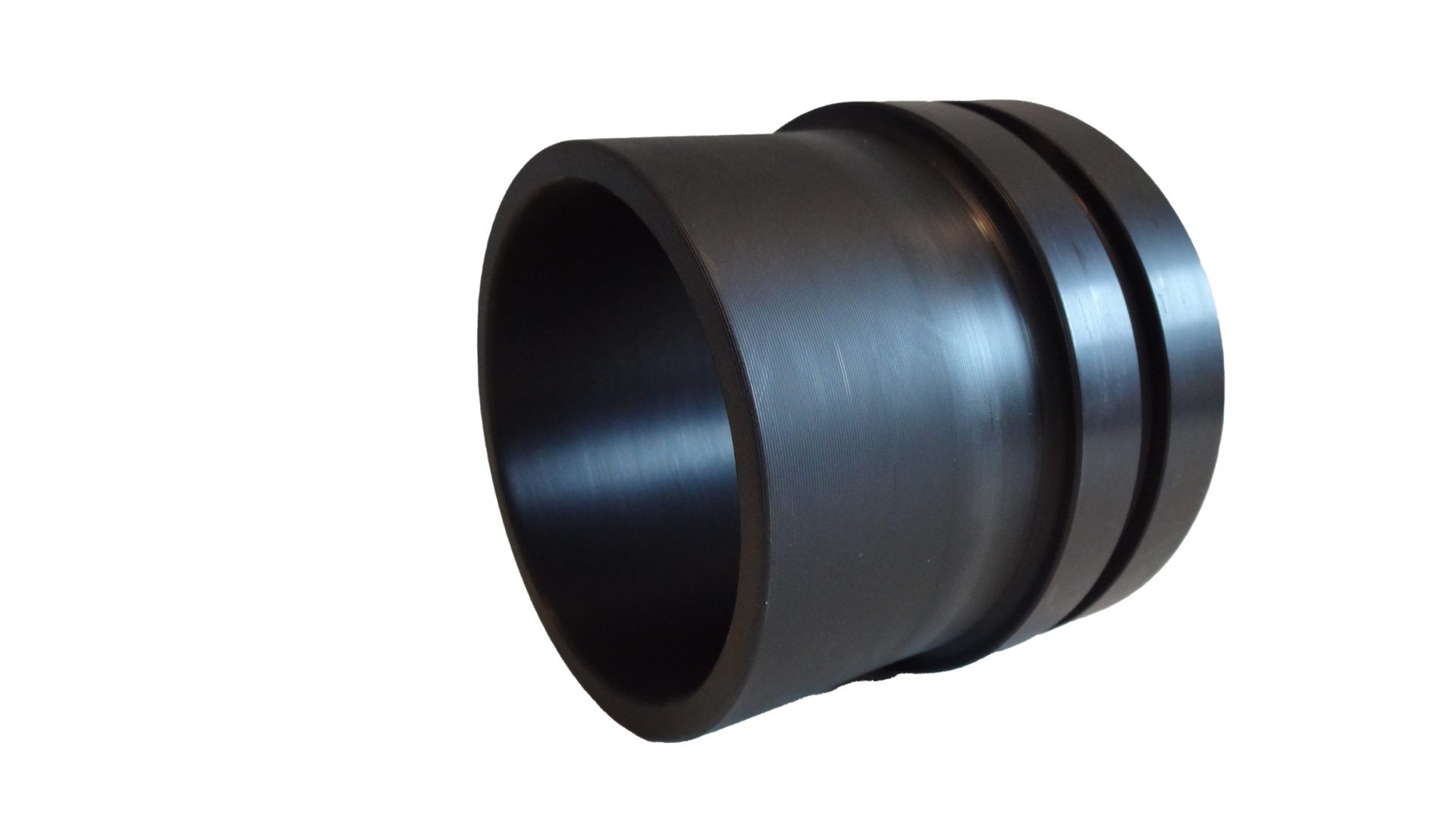

PE100 shouldered ends are an effective solution where pipe lines may need to be extended or rotated. The unique grooved pipe joining technology forms a robust pipe joint using a rigid coupling that prevents movement, in the same way as a flanged or welded joint.

We have had the range custom designed and manufactured to suit a range of projects and include the following features:

- Double reinforced shoulder for added strength. The couplings secure the pipe grooves to hold the pipes against high pressure thrust loads, without the need for additional restraints

- Fully moulded and void free manufacture for added reinforcement, providing end load bearing capabilities.

- Choice of short spigots and long spigots for ease of welding

- Reliable and easy to install.

- Large range of sizes from 63mm – 450mm

- SDR11 – SDR17

Click here to view the range or call us to learn more or place your order on 1300 789 178.